Wilson's Water Wells - Dual Rotary Drilling, Pumps, Sales & Service

Wilson's Water Wells Ltd.

The first step in the drilling process is to determine the most suitable location. Factors to be taken into consideration include: property boundaries, the location of any future buildings, ease of accessibility and the well’s position in relation to the septic bed.

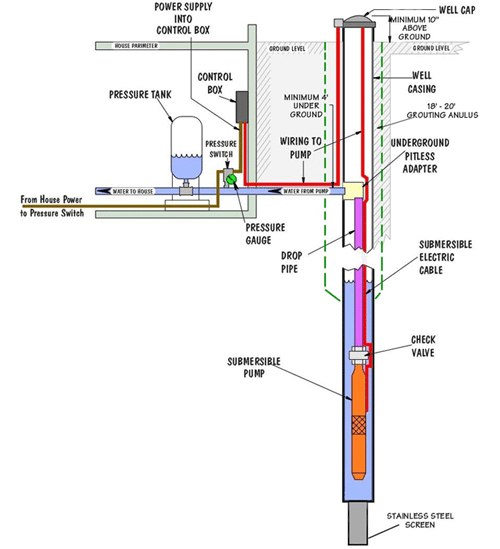

Once the ideal location has been determined, the actual drilling process can begin. During this process, the driller will continuously take soil samples to monitor the geology encountered. When a water bearing formation is found, the well casing and stainless steel screen are installed. The well is then developed until there is an adequate supply of clean water.

The next step is to perform a flow test to determine the capacity (gallons per minute) of the well. The annulus of the casing is then sealed with Bentonite grout to prevent any contaminants from entering the water supply.

Lastly, the pump os installed and the well is chlorinated and capped. Congratulations! You can now enjoy the naturally clean taste of well water.

Well Drilling Process

Drill Bit